Mail us

Item NO.:

AL013Payment:

TT ,For products Prepaid 30%, 70% before shipProduct Origin:

ChinaColor:

NaturalGoods Stock:

3000Order(MOQ):

10Product weight:

0.05Shipping Port:

XiamenLead Time:

20days

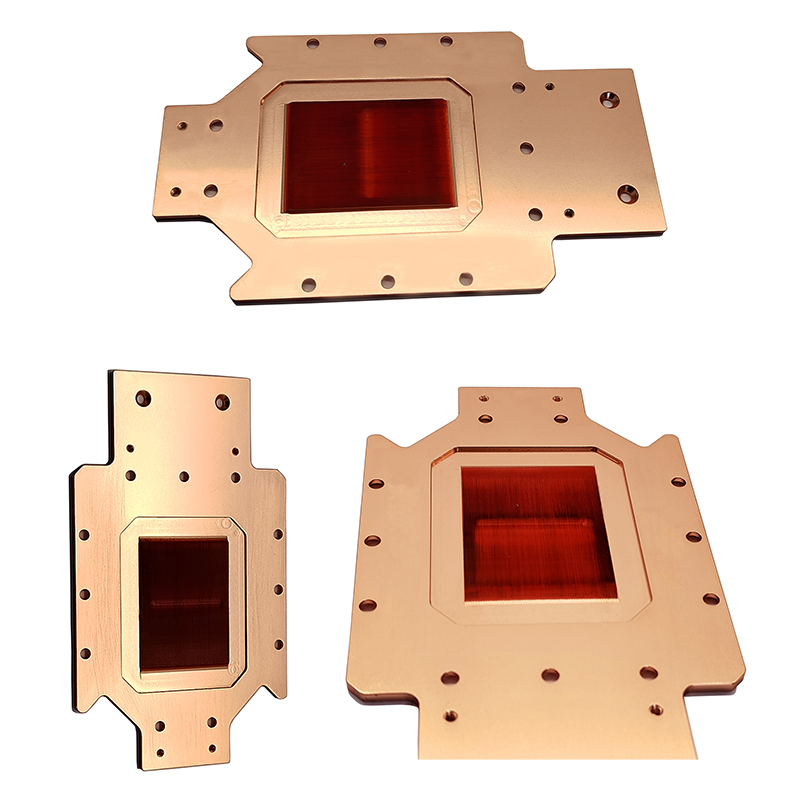

Copper shovel tooth heat sink

Use high thermal conductivity copper material C1100, specification: 6*80*120 (mm). The heat sink with 0.15 thickness * 0.3 pitch * 177 teeth is processed, and the accuracy of the teeth is within 0.01.

The benefits of the radiator produced by the shovel tooth process are as follows:

(1) The shovel-tooth radiator has a higher heat sink density and improves heat dissipation performance;

(2) The height of the blades of the shovel-tooth radiator can reach 120mm, which fully meets the production requirements of most radiators;

(3) The teeth of the shovel-tooth radiator can be made thinner, which can be 0.05mm-2mm, which can make the radiator lighter;

(4) The shovel-tooth radiator is shoveled on the prototype material, so the heat dissipation efficiency is not damaged, reaching 100% of the heat dissipation efficiency of the prototype material, and there will be no risk of loosening and falling, improving the reliability of machine operation;

(5) The shovel-tooth radiator has high compatibility, and the possibility of later processing is also great. It can also cooperate with buried copper pipes and other processes to improve the heat dissipation performance;

(6) The performance and efficiency of the shovel tooth machine have been continuously improved, and the continuous improvement of the shovel tooth material has made it suitable for mass production.

The shovel radiator has the following advantages:

(1) The shovel-tooth radiator is formed by forming an aluminum (copper) plate through the shovel-tooth processing process at one time. The FIN and the substrate are integrally formed without contact, which can exert the heat dissipation characteristics of efficient conduction.

(2) The shovel technology of the hardware can make the fin thinner and higher (thinner than the FIN of the aluminum extrusion profile), so the FIN density is high, and the heat dissipation efficiency is also higher.

(3) Since the processing technology is integrated by shoveling, the same heat dissipation area, the shoveling process can make the weight of the radiator lighter and the material cost is lower.

(4) Compared with aluminum extrusion and other processes, FIN can be made wider and higher with less restrictions on size and can be used for heat dissipation of larger power chips.

(5) For small-batch, large-volume radiators, the shovel teeth can be processed with plates, which saves expensive mold fees!

(6) Due to the continuous increase of chip heat generation in recent years, the improvement of tooth shovel technology and raw material processing technology, the 1060 plate and substrate buried heat pipe technology has become a highlight of large-scale heat dissipation assembly!

Prime is an excellent manufacturer of high-end radiators in China. The high-efficiency CNC gear shoveling machine and gear shoveling process independently researched and developed have been widely used in the production of high-power radiators. The products are used in photovoltaic inverters and wind energy converters. Radiator, new energy vehicle power battery pack heat dissipation, etc. In terms of production capacity, Shuyun Hardware has a number of large-scale CNC shoveling machine tools, which can meet the production of large quantities of radiators, and the delivery time is guaranteed. In terms of technical personnel, Shuyun has a large number of mature processing technology engineers to ensure that shoveling radiators Production quality.

The integrated production of the heat sink has stable heat transfer performance, greatly improved heat dissipation area, heat dissipation efficiency and longer life of heating elements. Products are used in military industry, new energy, communications, servers, industrial computers, large equipment, LEDs and other places that require rapid heat dissipation.

This is a high-quality and high-efficiency radiator. It has been precision processed and has a smooth surface without burrs.

Advantages of shovel tooth aluminum heat sink

1. The heat sink and the heat dissipation substrate use a piece of profile, and there is no connection point, and the heat conduction efficiency can reach 100% of the profile material.

2. The shovel cutter can process the heat sink very thin (thinner than the cut profile heat sink) and improve the heat dissipation efficiency

3. The CNC machining process of the shovel teeth of the heat sink is simple

Processing method: chipping fins

Surface treatment: outside anti-oxidation treatment

Size: 6*80*120(mm)

Material:copper

colour:As shown

Package Contents:

1 * Pure copper radiator

Only the above package content, other products are not included.

Note: Light shooting and different displays may cause the color of the item in the picture a little different from the real thing. The measurement allowed error is +/- 1-3cm.

Leave A Message

Leave A Message