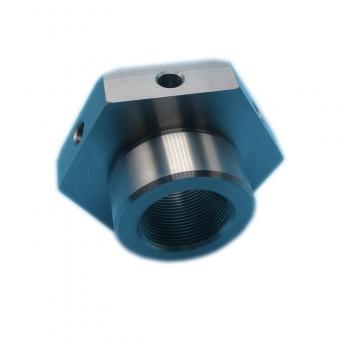

POM (Polyoxymethylene), also known as Delrin and Acetal, is an engineering thermoplastic characterized by its high stiffness, good machinability, excellent rigidity, low friction, high accuracy, and high dimensional stability, as well as chemical and abrasion resistance, these properties make it a great material in plastic CNC machining. POM materials are often used to make precision parts for a wide variety of applications. Typical uses of CNC POM machined parts include mechanical gears, guiding elements, connector components like nuts and screws, and various custom POM parts. If you are looking for a POM CNC machining company, Junying provides Delrin machining services for many years and specialized in POM milling, turning, and drilling. There are PTFE-filled Acetal, glass-reinforced Acetal, FDA-compliant Acetal, food-grade POM, medical grade POM, and more grades to choose from.

Benefits of POM Plastic Material

-

Alternatives to some traditional metal materials

-

Used in electronic, mechanical, automobile, building, medical, etc.

-

Outstanding machinability and some excellent properties

-

High tensile & impact strength and good rigidity

-

Good dimensional stability and creep resistance

-

Good wear resistance and chemical resistance

Describe

Industries Served : Machinery, Electronics, Automatic equipment, Hardware, Automobiles, Computers, Chemical, Medical instrument, Defense, Printing etc.

Equipment List: DMG 5 axis CNC machining center / HASS composite CNC machine / CNC Machining Center / CNC Lathes / Grinding Machines/ Milling Machines / Lathes / Wire-cuts / Laser Cuts / CNC Shearing Machines / CNC Bending Machines / etc.

Capabilities: CNC Turning, CNC Milling, Wire EDM Cutting, Metal Fabrication, Grinding, Laser Cutting, Welding, Assembling, Plastic Injection Molding,Photo Chemical Milling, CNC Plasma Cutting, CNC Turret Punching, Waterjet Cutting, Secondary Processes, Laser Marking Services etc.

Materials Capabilities: Aluminum Parts, Brass Parts, PTFE Parts, Copper Parts, Steel Parts, Acetal Parts, Stainless Steel Parts, Polycarbonate Parts, Polystyrene Parts,Sheet Metal Parts, Fiberglass Parts, Carbon Fiber Parts, Nylon Parts, Titanium Parts, ABS Parts, PVC Parts, Sterling Silver Parts, Spring Steel Parts,Bronze Parts, Plastic Parts, Rubber Parts, Acrylic Parts etc.

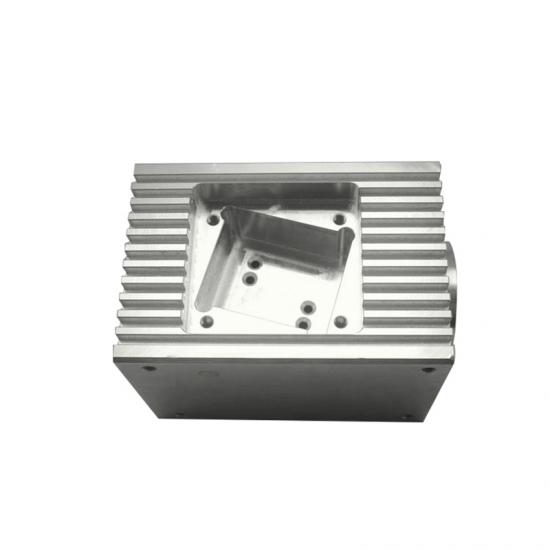

Custom Machined Parts: Auto Parts, Electronics,Enclosures, Flat Washers, Front Panels, Gaskets, Golf Putters, Heatsinks, Jewelry, Knobs, Machinery, Metal Brackets,Metal Spacers, Motorcycle Parts, Pulleys PVC Parts, Robot Parts, Shaft Supports, Sheet Metal Boxes & Enclosures, Shift Knobs, Spring Spur Gears,Steel Shafts, Toy Parts, Wrenches

Surface Treatment: Anodizing/Black Oxide/Electroplating/Heat Treating/Brushing/Grinding/Polishing/Painting/Powder Coating/Nickel Plating/Galvanized

Inspection Equipment: Mitutotyo three-coordinate measuring machine, Mitutoyo Tool Microscope can measure up to 300mmX x 175mmY x 220mmZOuter Micrometer,Inside Micrometer (Machine), Digimati Micrometer, Internal Micrometer, Mechanical Caliper, Vernier Caliper, Caliper (Digital), Calipe (Machine),Caliper (Dial), diameter Scale, Depth Micrometer, Digital Caliper, Altitude Gauge, Electric Balance, 2D Measurement Inspection Instruments etc.

Q C: Incoming material will be checked carefully before production.

Strict processing quality control.

100% inspection before shipment.

Quality Assurance & Customer Satisfaction

Located in Xiamen, Fujian, China (Mainland), VOHN manufactures custom parts for clients ranging from government agencies and Fortune 100 companies to inventors, engineers, hobbyists, and students.

To consistently exceed customer expectations, quality control and assurance is achieved through

Detailed records of incoming raw materials

-

Detailed records of incoming raw materials

-

Detailed computer generated traveler tickets

-

Analysis of root cause of non-conformances

-

Fully equipped inspection department

-

Multi-level incoming order review

-

Fully equipped inspection department

-

Periodic calibration and labeling of inspection tools

-

Comprehensive written procedures and policies

-

Designated areas for nonconforming parts

-

Corrective actions to prevent recurrence of non-conformances

-

Daily backup of electronic records stored in multiple locations

-

Extensive electronic records of orders, customer communications, and inspection results

-

Comprehensive software expert system advising customers of manufacturability issues

-

Staff members being strongly encouraged to suggest improvements in methods, materials, and suppliers

F A Q

русский

русский español

español 中文

中文

Leave A Message

Leave A Message

IPv6 network supported

IPv6 network supported