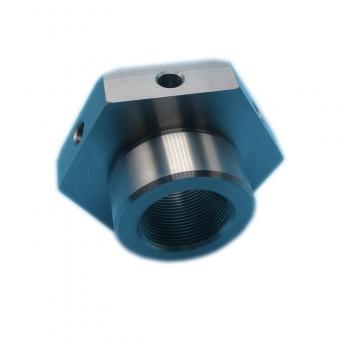

Stainless steel custom cnc processing parts

1.Stainless steel custom fabrication produce depend on deep drawing

2.It is a cnc stainless steel turned part

3.Made by cnc machining precision cnc turning parts

Specification of this stainless steel custom cnc processing parts

1.Stainless steel custom fabrication produce depend on deep drawing

2.Tt is a cnc laser cutting diy stainless steel turned part

3.Made by cnc machining precision cnc turning parts

Parameters of this stainless steel custom cnc processing parts

|

Material

|

Stainless steel(can be metal and plastic, aluminum alloy, zinc alloy, brass)

|

|

Color

|

Customized ,golden,Sliver and other (all the color can be )

|

|

Design

|

Customized

|

|

Tolerance:

|

0.01mm

|

|

MOQ

|

One piece

|

|

Price

|

FOB, EXW,CIF, price, contacts us for wholesale price

|

|

Packing

|

A plastic bag, then a carton as outer packing. Dozens of them be packed one carton.

|

|

Shipment

|

1. The sample is transported by air.

2. A large quantity will be transported by sea or air (depend on you )

|

|

Payment

|

1. By T/T 30% deposit and 70% balance be paid before delivery.(Accept L/C)

|

|

Logo

|

Can do sticking or painting

|

Description by Manufacturer

The quotation on the webpage is for reference only, Unit price according to the sample.

PRIME is a company with years of professional experience in the production of precision bolts, screws, nuts & machining parts and other products.

Our team of technical experts specializes in cooperating with customers to develop various customized products.The products have been widely used in automobiles, home appliances and medical devices.

We handle many other type of materials. Please contact us if your required material is not listed above.

Application

Machine spare parts,Motor Machinery Electric Tools,Sports Apparatus,kitchenware,office equipment,Scooter Aluminium windows,Shower blocks,hanging round,closet wheel,toys.etc

Quality Assurance & Customer Satisfaction

Located in Xiamen, Fujian, China (Mainland), prime manufactures custom parts for clients ranging from government agencies and Fortune 100 companies to inventors, engineers, hobbyists, and students.

To consistently exceed customer expectations, quality control and assurance is achieved through

Detailed records of incoming raw materials

-

Detailed records of incoming raw materials

-

Detailed computer generated traveler tickets

-

Analysis of root cause of non-conformances

-

Fully equipped inspection department

-

Multi-level incoming order review

-

Fully equipped inspection department

-

Periodic calibration and labeling of inspection tools

-

Comprehensive written procedures and policies

-

Designated areas for nonconforming parts

-

Corrective actions to prevent recurrence of non-conformances

-

Daily backup of electronic records stored in multiple locations

-

Extensive electronic records of orders, customer communications, and inspection results

-

Comprehensive software expert system advising customers of manufacturability issues

-

Staff members being strongly encouraged to suggest improvements in methods, materials, and suppliers

F A Q

русский

русский español

español 中文

中文

Leave A Message

Leave A Message

IPv6 network supported

IPv6 network supported